In the intricate world of fashion and garment construction, there exists a quiet hero, often overlooked but undeniably essential – NonWoven interlining. While fabrics, patterns, and stitching techniques capture our attention, it’s the unseen layers that truly define the quality, structure, and durability of our clothing.

Non-woven interlining, with its remarkable properties and versatile applications, serves as the invisible backbone of many garments, providing reinforcement, support, and shape where needed. In this comprehensive exploration, we peel back the layers of mystery surrounding non woven interlining, revealing its transformative magic and its vital role in crafting garments of exceptional excellence.

Understanding Non-Woven Interlining

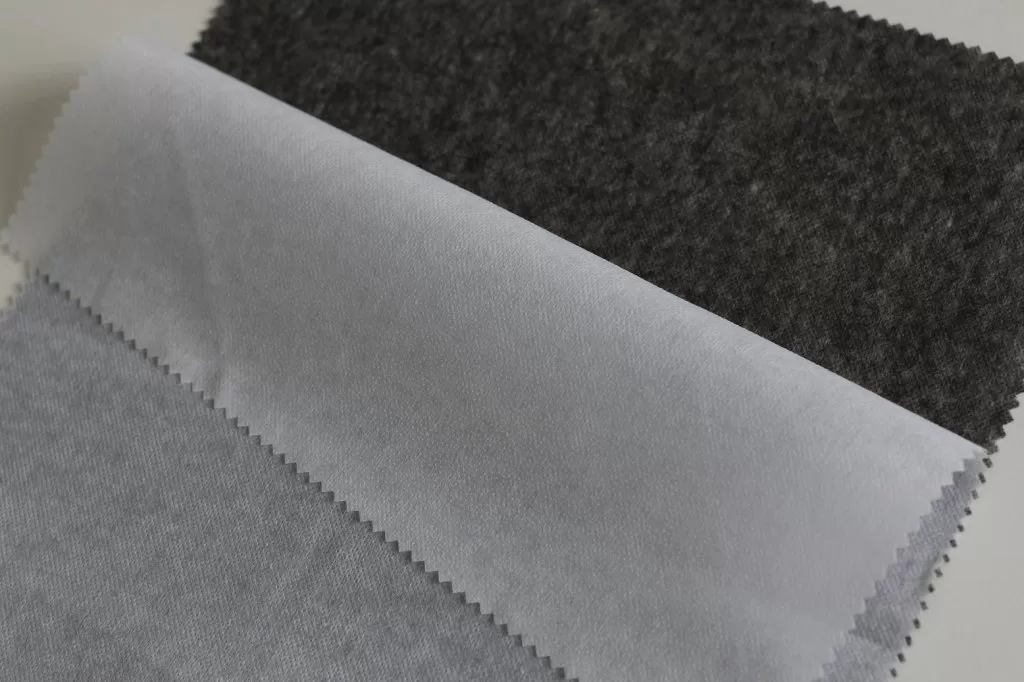

To appreciate the magic of non-woven interlining, we must first understand its composition and manufacturing process. Unlike traditional woven fabrics, non-woven interlining is created by bonding fibres together using heat, pressure, or chemicals, resulting in a fabric-like material that offers unique properties such as flexibility, resilience, and dimensional stability.

The Role of Non-Woven Interlining in Garment Construction

Non-woven interlining serves as a versatile tool for garment makers, offering reinforcement and support in critical areas such as collars, cuffs, and waistbands. By adding structure and stability, interlining ensures that garments maintain their shape and drape beautifully on the body, enhancing both comfort and aesthetics.

Types and Applications of Non-Woven Interlining

From lightweight fusible interfacings to heavy-duty stabilizers, non-woven interlining comes in a variety of forms to suit different fabric weights, garment styles, and construction techniques. Whether used for shaping, stabilizing, or embellishing, interlining offers endless possibilities for enhancing the quality and design of garments.

Innovations and Sustainable Alternatives

As the fashion industry evolves, so too does the technology and materials used in garment construction. Innovations in non-woven interlining include eco-friendly options made from recycled fibers or biodegradable materials, offering a sustainable alternative to traditional interfacings without compromising on performance or quality.

Tips and Techniques for Working with Non-Woven Interlining

Working with non-woven interlining requires careful attention to detail and proper technique to achieve professional results. From selecting the right type and weight of interlining to properly fusing or sewing it into place, mastering the art of interlining is essential for creating garments that stand the test of time.

Non-woven interlining may be invisible to the naked eye, but its impact on garment quality and design is undeniable. By understanding its properties, exploring its applications, and embracing innovations in sustainable materials, we can truly unlock the magic of non-woven interlining and elevate our garment-making skills to new heights of excellence.

Non-Woven Interlining in Action

To truly grasp the significance of non-woven interlining, let’s delve into real-world examples where its magic shines bright. From haute couture creations to everyday essentials, non-woven interlining plays a pivotal role in shaping the garments we wear and love.

High-Fashion Couture: Explore how renowned fashion houses utilize non-woven interlining to achieve impeccable structure and precision in their runway-worthy creations. From sculptural silhouettes to intricate details, see how interlining elevates garments to works of art.

Tailoring Mastery: In the world of bespoke tailoring, non-woven interlining is the unsung hero behind perfectly fitted suits, jackets, and coats. Discover the techniques used by master tailors to incorporate interlining seamlessly into their garments, ensuring both form and function.

Everyday Essentials: Even in everyday clothing items like shirts, dresses, and skirts, non-woven interlining plays a crucial role in enhancing comfort and durability. Explore how interlining reinforces collars, plackets, and hems, adding longevity to wardrobe staples.

Exploring the Future of Non-Woven Interlining

As technology advances and consumer preferences evolve, the future of non-woven interlining holds exciting possibilities. From smart textiles that adapt to the wearer’s needs to sustainable innovations that minimize environmental impact, the journey of non-woven interlining is far from over.

Smart Textiles: Imagine garments that regulate temperature, monitor health metrics, or even generate energy – all made possible through advancements in nonwoven interlining technology. Explore how smart textiles are revolutionizing the way we think about clothing.

Sustainable Solutions: With sustainability becoming increasingly important in the fashion industry, non-woven interlining manufacturers are exploring eco-friendly alternatives and innovative recycling methods. Learn about the latest developments in sustainable interlining materials and production processes.

As we conclude our journey through the magic of non-woven interlining, one thing becomes clear – its potential is limitless. From its humble beginnings as a supporting player in garment construction to its role as a catalyst for innovation and sustainability, non-woven interlining continues to shape the future of fashion. By embracing its versatility, harnessing its power, and pushing the boundaries of what’s possible, we can unlock new realms of creativity and excellence in the garments we create and wear.

Leave a Reply